BNSF helping to fuel a sustainable tomorrow

Used restaurant cooking oil, tallow and municipal solid waste might not be what most consider the next “big thing” given their “eww” factor, but these raw materials are gaining new respect as a solution to meeting the world’s needs for sustainable energy. That’s because they’re considered feedstocks, which are needed to produce biofuels, or renewable fuels.

Feedstocks come from plants, algae and organic waste. Sources include corn, sugarcane, wood chips, sawdust, crop residues and more. Vegetable oils extracted from soybeans, canola, sunflowers and other seeds are also feedstocks.

“Renewable fuels are becoming a game-changer as they’re an environmentally friendly alternative to fossil fuels,” Phillip Lowery, director, Marketing for Agricultural Commodities at BNSF, explained. “At one time, meat processing companies had a byproduct that they had to get rid of and now they have incentive to sell them to refiners.”

Biofuel production is taking off, especially in places like California and Washington, states that have set low-carbon fuel standards and are offsetting those with tax incentives. Thanks to these government programs and sustainability goals that industries and countries are setting, the global demand for biofuels is estimated to grow by nearly 20 percent in the five years, according to the International Energy Agency.

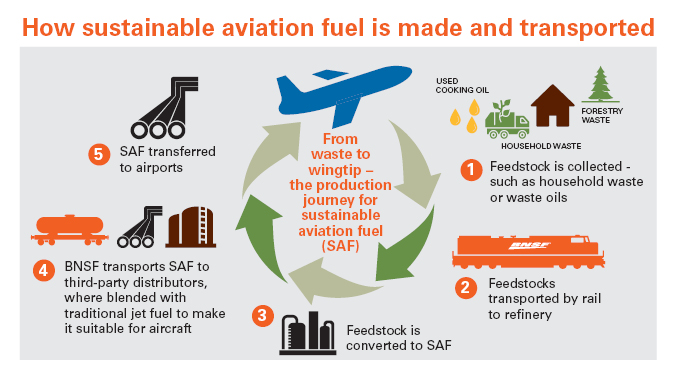

For more than two decades, BNSF has been moving renewables, like ethanol made from corn and other plant materials. More recently, renewable diesel has been riding the rails (and being tested in our locomotives for about three years) and we anticipate moving more biodiesel as well as sustainable aviation fuel (SAF), or liquid hydrocarbon jet fuel.

Recently, BNSF joined forces with Calumet/Montana Renewables to ship the producer’s SAF to market.

The SAF is produced in Great Falls, Montana, by Calumet’s refinery, Montana Renewables. It then moves by rail to Portland, Oregon, where it’s stored in large holding tanks. From there, the SAF is loaded onto vessels for the journey down the West Coast to consumption points such as Los Angeles Airport. Amidst the supply chain journey, the SAF is bought by a third-party, which then sells it to commercial airlines.

Montana Renewables has been a petroleum refinery for decades, and BNSF has moved petroleum products for them through the years. Montana Renewables invested in capital enhancements to its facility to allow for greater production of SAF and to improve the efficiency of loading and shipping that SAF by rail. Current volume expectations are about 1,825 carloads of SAF per year. But that could be just the beginning.

Currently Montana Renewables is the country’s largest producer of SAF, at 53 million gallons of SAF a year, which is less than 2% of President Biden’s goal to increase U.S. production of SAF to 3 billion gallons a year by 2030.

While BNSF is part of the supply chain to transport renewable fuels, we also bring the inbound feedstocks needed for renewable fuel production. With supply critical for keeping up with demand, more crushing facilities that crack and extract these oils are being built in the Upper and Central Plains and near our rail lines.

To support these customers’ transportation needs for both feedstocks and the renewable fuels, BNSF is working closely with producers and refiners to find solutions to bring their products to market efficiently and investing capital where appropriate.

“Gallon for gallon, the costs are still high to produce renewable diesel,” Lowery explained. “Companies can either build new refineries, convert petroleum-producing refineries into those that can produce renewable fuels, or they can have a hybrid facility, one that can co-process. By being relationship-focused, we can help these customers find efficient rail solutions by capitalizing on existing network and capacity.”

One example of these joint solutions is with customer Marathon Petroleum Corp. (MPC), which is focused on increasing the renewable fuels they produce. In 2021, MPC converted its petroleum refinery at Dickinson, North Dakota, to a renewable diesel facility. The company also made investments to repurpose facilities in Nebraska and Ohio to supply feedstocks, with BNSF providing transportation support. Once the renewable diesel was produced, BNSF and MPC developed the first-ever unit train solution to transport the product to market.

In addition to dedicated unit train service, Lowery and others at BNSF are working on transportation service plans to improve efficiency and reduce transit times for these customers.

“We’re looking at ways we can aggregate the carloads in our manifest network, and then build those into unit trains,” Lowery explained. “Our Service Design team has been instrumental in creating unique but achievable operating plans that our Transportation Department has worked hard to successfully deliver.”

Recognizing the potential of this business and wanting to accelerate it, our Service Design team has built-in service offerings that not only provide dedicated unit trains, so less handling of individuals cars, they have found ways to “block” cars into groups, again to reduce handling and transit time.

“We’re collaborating with all parties in the marketplace to provide faster transit times, as well as provide a dedicated and more consistent railcar supply and network capacity,” Jon Gabriel, vice president, Service Design said. “Cultivating these relationships provides the industry solutions that allow BNSF to be the recognized transportation leader.”

An example of how we’re creatively building-in and working with others is the design, capacity infrastructure and service to support the Diamond Green Diesel facility in Port Arthur, Texas. This facility opened in 2022 with substantial rail, above ground tank storage and railcar loading and unloading capabilities. It is designed to handle significant quantities of inbound and outbound railcars on a daily basis. BNSF worked with a rail terminal partner in the area on a capacity and switching agreement to ensure additional track and handling services for years to come.

“As this business matures, we’re working to balance resources and capital,” BNSF’s Group Vice President Agricultural Products Angela Caddell said. “That requires lots of communication with our customers and partners, including feedstock shippers, refineries and other transportation providers. There are many players involved in this game-changing energy source, but it’s one that, working together, we believe can bring a brighter, cleaner future.”

And that’s a commodity worth any “eww” factor.