Locomotive winterization: Avoiding ice, ice, baby

Winter weather calls for a time to “stop, collaborate and listen” – as in “Ice Ice Baby” lyrics by rapper Vanilla Ice. This mindset is the same at BNSF. Colder temperatures have arrived across much of our network, and to maintain safe, efficient service throughout the season, our mechanical teams complete a special locomotive maintenance process known as winterization.

“In winter, trains are at higher risk for airbrake-related issues as colder ambient temperatures increase the potential of freezing any moisture present in compressed train line air,” Abid Raza, general director of locomotive maintenance and reliability, said.

For trains to safely operate, air must flow throughout the trainline for the brakes to function properly. Locomotives supply the air that is compressed by an air compressor, which then flows through the train line via series of reservoir tanks and controlled through electronic or manual controls in the locomotive cab. Additionally, each railcar has an air tank (reservoir) that is charged with this compressed air through the brake pipe. When winter rolls around, locomotives and freight cars need to be prepared to withstand the colder elements.

“Winterization is all about removing moisture in the trainline air to the greatest extent possible and preventing any moisture that is present from freezing – all to maintain good air flow,” Raza said.

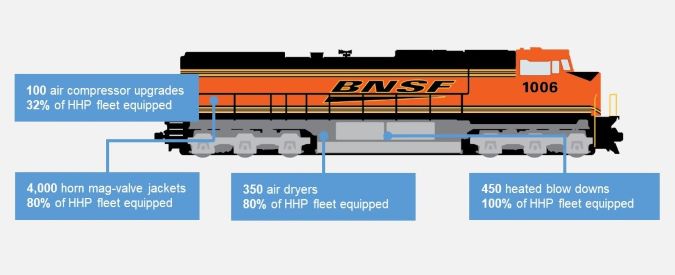

Over the past six years, BNSF has invested in various winterization modifications such as air dryers, heated blowdowns, and horn mag-valve jackets to tackle the ever-increasing winter challenges. Also, every autumn, all locomotives go through a series of checks during maintenance to ensure that all the key winter components are in good order and functioning as intended. A locomotive that has gone through the winter modifications, along with the winter checks, is a winter-weather veteran and ready for the season ahead.

“Operating through winter is an evolving process, and every year we learn and adapt while looking ahead to the next season,” Raza added. “The feedback we receive from the field has immensely helped our journey toward perfect winter performance.”

One example of BNSF’s adaption to the winter is a new technology known as heat tape. Just like it sounds, heat tape is tape that heats and is designed to be wrapped on a locomotive’s main reservoir pipe to keep the moisture in the air from freezing.

“Heat tape is currently being tested on 60 locomotives with 100 expected to be equipped by the end of the year,” Raza said. “If heat tape works effectively, this will remove one of the key challenges we see every winter and will have eliminated the need to relocate the main reservoir pipe or add water separator.”

With the days getting shorter and the weather colder, Jack Frost is nipping at the noses of our locomotive fleet. The noses – or front ends – of locomotives are winterized by equipping headlights with heaters to melt the snow and ice. To ensure that the train’s horn system remains operational, we install an insulation jacket to cover the horn mechanism.

Thanks to these extra steps, and field feedback and response we’ve reduced our locomotive-related service interruptions in our North Region by 8%.

“We’ve come a long way in our winterization efforts,” Raza said. “Working against Mother Nature’s elements can be challenging, but we look forward to the ever-evolving journey.”